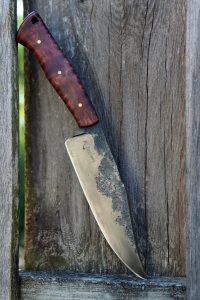

A clip point with a quilted birds-eye maple handle:

A clip point with a quilted birds-eye maple handle:

Along with my first knife experience attendee (a custom experience his wife bought for him for Christmas), I made a knife just like his alongside him as I demonstrated what to do next.

A lovely lady in my area called me up, asking for an experience for her husband in knife-making. I wasn’t quite set up for my experiences, but this young man came over and dealt with my messy shop and we forged out a knife together. He described to me what he wanted, and I made one along with him, step-by-step.

He chose to make a clip-point knife with an Osage orange handle and mosaic pins.

Here are his words about the experience:

“I had the opportunity to have Ross walk me through forging a knife. I’ve always wanted to give forging a try. I recently started watching Forged in Fire and it made me want to make something even more, so my wonderful wife reached out to Jagears Knives and Smithy for a Christmas present. Contacted Ross and he helped me decide on what kind of knife to make. Went to his workshop, fired up the forge, and he walked me through the process allowing me to do most of the work and corrected when necessary. Ross is super knowledgeable, was able to answer all questions in detail ,and explain in terms easy to understand. I really enjoyed learning to make this knife and would recommend this to anyone that has ever wanted to forge a knife. I hope to one day have my own forge and I know if I have any questions I can ask for his advice and he would be more than willing to help me. Really was a pleasure and I’m happy with my knife. Thank you very much for your patience and kindness it was a great learning experience!“

This is the first knife I’ve used Micarta on and a sculpted handle where the spine’s profile is a Coke bottle with wide hips and a pinky groove. The blade is 1084, the hilt is 304 stainless steel, the handle is Micarta with a mosaic pin and a throng hole. Just like all my knives, I enjoyed making it and learned a lot about working the Micarta which is very much different than the other materials I’ve worked with.

The scabbard is handmade as well. It’s my first pouch scabbard. I watched a tutorial from Ian Atkinson and thought it would work well with this knife.

The scabbard is handmade as well. It’s my first pouch scabbard. I watched a tutorial from Ian Atkinson and thought it would work well with this knife.

Save

Thought I’d mention why I haven’t kept my site updated this past year. My webmaster has been busy with our newborn baby boy, who now is a little over a year old, and her new adventure as being a published author.

BUT there are now four more knives just below this post for you to see now!

For those of you who like to read or have loved ones who like to read, especially if you like historical romance, give it a try, the first is free on ebook, the rest can be found wherever you buy books.

For those of you who like to read or have loved ones who like to read, especially if you like historical romance, give it a try, the first is free on ebook, the rest can be found wherever you buy books.

Thank you for your patience and understanding! Merry Christmas and may God richly bless you!

Thank you for your patience and understanding! Merry Christmas and may God richly bless you!

Special order hunting and skinning knife with an antler provided by the customer. This is the first knife I’ve used locator pins for the furniture and handle pieces. Wow, what a difference they make. The blade is 1084 with a gut hook and vine pattern filework on the spine, and I used a checkering file to provide the thumb grip on the spine. The hilt, pommel and subhilt are brass. Between the hilt and subhilt are stacked leather. At both ends of the antler are leather gaskets so that with heating and cooling and humidity changes the antler can expand and contract without cracking.

Special order hunting and skinning knife with an antler provided by the customer. This is the first knife I’ve used locator pins for the furniture and handle pieces. Wow, what a difference they make. The blade is 1084 with a gut hook and vine pattern filework on the spine, and I used a checkering file to provide the thumb grip on the spine. The hilt, pommel and subhilt are brass. Between the hilt and subhilt are stacked leather. At both ends of the antler are leather gaskets so that with heating and cooling and humidity changes the antler can expand and contract without cracking.

The scabbard is unique. I saw on a cover of a magazine, but with no explanation as to why, the flap of leather underneath the snap caught my eye. That made me think I wanted to try it, to keep the snap from damaging the knife. Inside the pocket is a DMT diamond stone. I hope it skins many deer.

The scabbard is unique. I saw on a cover of a magazine, but with no explanation as to why, the flap of leather underneath the snap caught my eye. That made me think I wanted to try it, to keep the snap from damaging the knife. Inside the pocket is a DMT diamond stone. I hope it skins many deer.

A dear friend who was a production test pilot wanted a knife reminiscent of the Kukri knife but capable of being strapped to his forearm so while he was in the crash position if he survived, he could access his knife. This is the closest I could come to marrying those two desires.This is one of few that I didn’t forge. The knife is made out of 1095 and cold blued.

The sheath is Kydex made to fit on a Ace Carpal Tunnel Bandage. 🙂

My mom wanted me to make a knife for my dad’s birthday and to use this Lignum Vitae he raised from the bottom of the Panama Canal while Scuba Diving when we lived there. Being that my dad is a sailing instructor, I thought the only kind of knife he would actually use would be a seafaring knife. I used the lignum vitae for the furniture and cork for the handle in the hopes that it would float. It doesn’t. This is the first knife that I etched with ferric chloride. I think it turned out great.

The sheath is thrown away Kydex and designed to be worn either on the belt or as a neck knife.

A friend asked if I could come over to teach him how to make knives with his propane forge. I’ve never used a propane forge and told him that. When trying to decide what would be easiest to make, I came across Joe Keeslar’s Brute de Forge knives. I saw how the simplicity of the design lends itself to individual artistic license. So we decided to do the Brute de Forge. With this one, I thought I would try the clay hardening to see if I could get a hamon. And Viola! It worked. Needless to say, my friend and I had a blast making this.

I thought I’d keep this for my own EDC (Ever Day Carry), but someone offered me money and I let him take it off my hands.

It’s made out of a file of unknown brand. The handle is mahogany that is scrap from a machine shop. The pins are mosaic and the throng hole is stainless steel tubing.

It’s made out of a file of unknown brand. The handle is mahogany that is scrap from a machine shop. The pins are mosaic and the throng hole is stainless steel tubing.

We had trouble with out truck, so no pictures from the wife, but this picture was on the Little House on the Prairie website. You can see my friend, Mark Palmer, behind me. I enjoy my times demonstrating with him. Great guy.